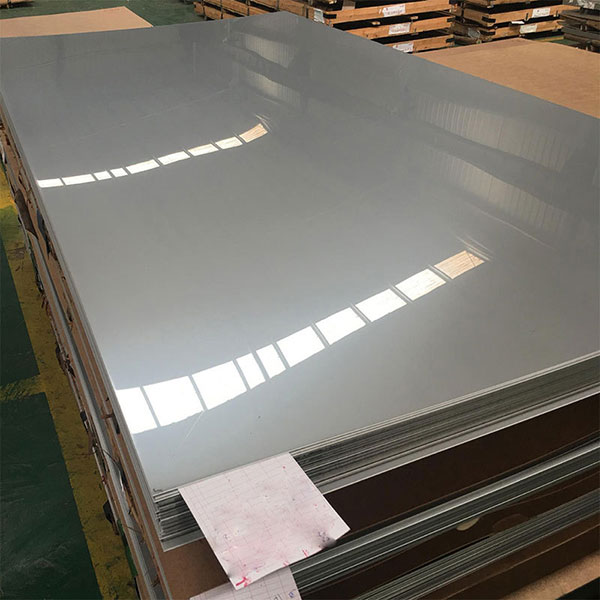

We specialize in producing and selling high-quality stainless steel plates, including grades such as 201, 304, and 316, to meet various requirements for corrosion resistance and heat tolerance. We also offer a range of surface treatments, such as mirror finishes, brushed finishes, and nickel plating. These plates are widely used in industries such as construction, decoration, industrial equipment, and food processing.

Features of Stainless Steel Plate

Heat Resistance: Stainless steel plates maintain their strength and shape in high-temperature environments, making them exceptionally reliable in applications involving heat.

Mechanical Properties: These plates offer excellent mechanical properties, including high strength, good toughness, and ductility, allowing them to withstand heavy loads and impact.

Workability: Stainless steel plates are easy to process and can be formed by cutting, bending, welding, and other methods to meet the design needs of complex structures.

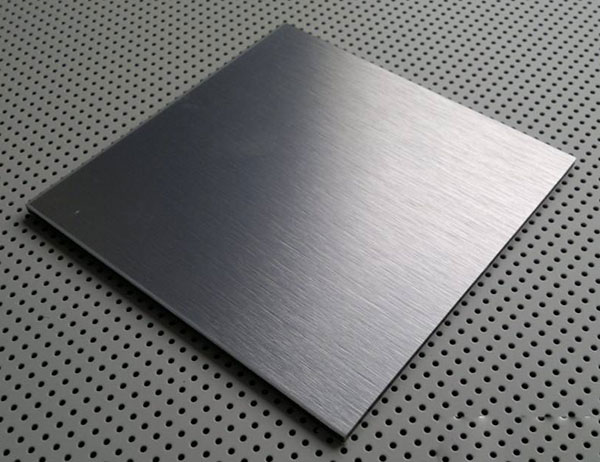

Surface Aesthetics: The smooth, metallic surface of stainless steel can be polished or brushed to achieve a mirror or matte effect, suitable for applications requiring high visual appeal.

Hygiene: Stainless steel plates are resistant to bacterial growth, easy to clean, and ideal for use in food processing, medical equipment, and pharmaceutical industries.

Diversity: Stainless steel plates come in various types and grades, such as 304 and 316, each offering specific properties for different applications. The right material can be selected to meet specific engineering needs.

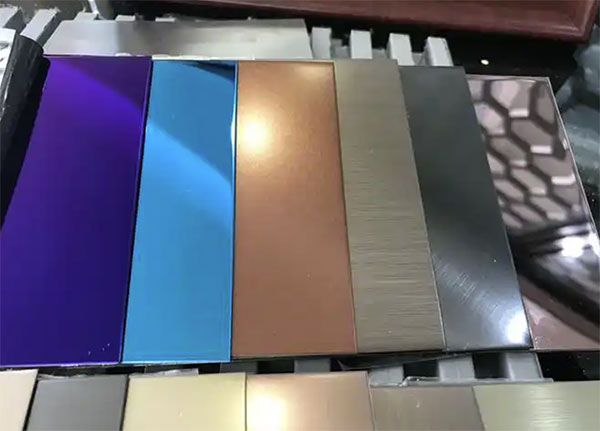

Stainless steel plate surface treatment process

Chemical Treatment: A layer of stable compounds is formed on the stainless steel surface through chemical or electrochemical treatment, such as nickel electroplating, phosphating, or chromate treatment, to enhance corrosion resistance and achieve decorative effects.

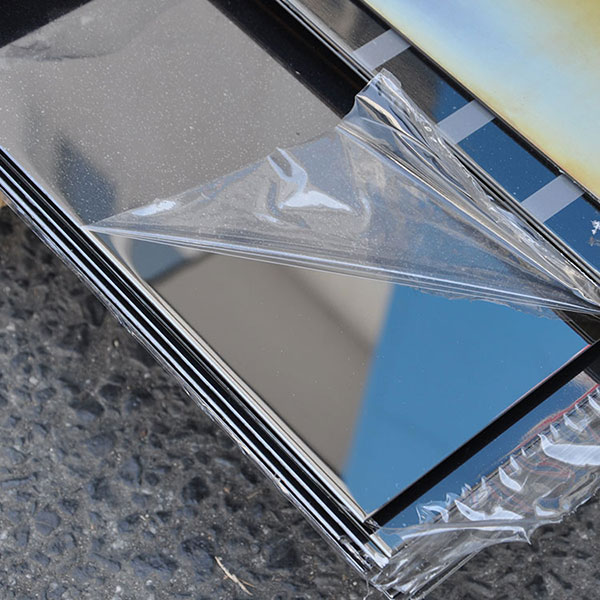

Mirror Treatment: The stainless steel surface is polished to a high-gloss mirror finish, often used for decorative purposes.

Surface Brushing: Textures like straight lines, random lines, and threads are applied to the stainless steel surface to provide a pleasing tactile feel and a wear-resistant finish.

Painting: Paint is sprayed onto the stainless steel surface to enhance appearance, corrosion resistance, and weather durability, offering various colors and effects.

Different between 201,304,316 stianless steel plate

201 Stainless Steel Plate

Chemical Composition: 201 stainless steel contains high levels of manganese and nitrogen, with about 16-18% chromium.

Features: It offers good workability and high strength, though its corrosion resistance is lower than that of 304 and 316 stainless steels.

Applications: Commonly used in architectural decoration, furniture, automotive parts, kitchen utensils, and other cost-sensitive applications where high corrosion resistance is not critical.

304 Stainless Steel Plate

Chemical Composition: 304 stainless steel contains 18-20% chromium and 8-10% nickel, making it one of the most widely used austenitic stainless steels.

Features: It has excellent corrosion resistance, good workability, and high strength, making it a versatile stainless steel material.

Applications: Widely used in food processing, medical equipment, chemical equipment, architectural decoration, kitchenware, and other applications.

316L Stainless Steel Plate

Chemical Composition: 316 stainless steel contains 16-18% chromium, 10-14% nickel, and 2-3% molybdenum.

Features: With the addition of molybdenum to the composition of 304 stainless steel, 316 offers enhanced corrosion resistance, especially in environments containing chloride ions.

Applications: Suitable for marine environments, chemical industries, the paper industry, medical equipment, and other applications requiring higher corrosion resistance.

Applications of Stainless Steel Plate

Construction: Stainless steel plates are commonly used in architectural features such as exterior cladding, roofing systems, railings, and handrails due to their corrosion resistance and aesthetic appeal, providing both durability and elegance.

Automotive Industry: Stainless steel plates are used in automotive exhaust systems, body panels, and decorative parts. Their corrosion resistance is particularly valuable in exhaust systems, where they contribute to vehicle safety and structural integrity.

Food Processing: Thanks to their smooth surface and corrosion resistance, stainless steel plates are ideal for food-contact applications, including processing equipment, storage containers, and work surfaces, ensuring high standards of hygiene and safety.

Medical Industry: Stainless steel's biocompatibility, corrosion resistance, and ease of sterilization make it suitable for surgical instruments, implants, and other medical devices, as well as for constructing hospital and clean room facilities.

Petrochemical Industry: Stainless steel plates can withstand high temperatures and corrosive environments, making them suitable for use in refineries, pipelines, and storage tanks where they encounter corrosive chemicals and gases.

Household Appliances: Stainless steel plates are widely used in household appliances, including refrigerators and ovens, for their rust resistance and easy-to-clean properties.

Art and Craft: Stainless steel’s workability makes it popular in arts and crafts, where it can be cut, welded, and formed into intricate designs.

Our stainless steel plates are designed to meet the unique demands of each application, providing quality, versatility, and durability across diverse industries.

|

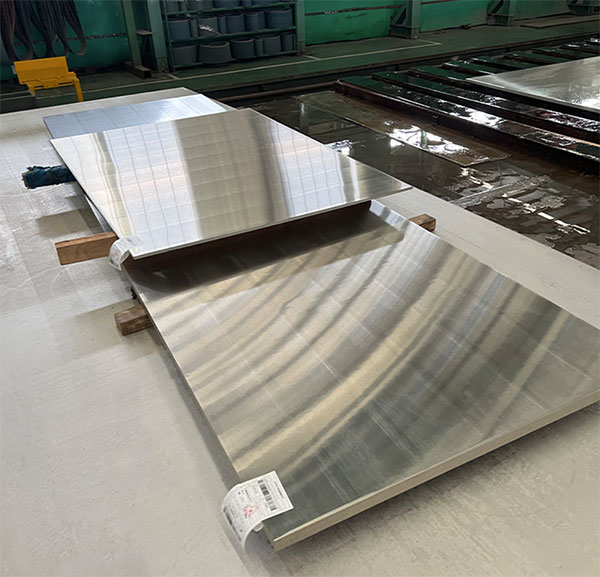

Product |

Stainless steel plate |

|

Material |

201, 304, 316, 430, 409, 310S, 904L,etc |

|

Surface treatment |

Original surface, mirror surface, bright surface, brushed surface,

Color picture, titanium, nickel plated |

|

Thickness(mm) |

0.1-100 |

|

Width(mm) |

500-2000 |

|

Length(mm) |

1000-6000 |

|

Tolerance(mm) |

±0.02 - ±0.15 |

|

Package |

Waterproof paper, wooden boxes, pallets, etc. |

|

Application |

Building decoration, industrial equipment, food processing, medical equipment,

chemical equipment, automobile manufacturing, etc. |