Aluminum plastic composite sheet brief

Aluminum plastic composite sheet is composite materials that use chemically treated coated aluminum panels as the surface material, polyethylene plastic or high minerals as the core material, and are processed on special aluminum plastic panel production equipment.

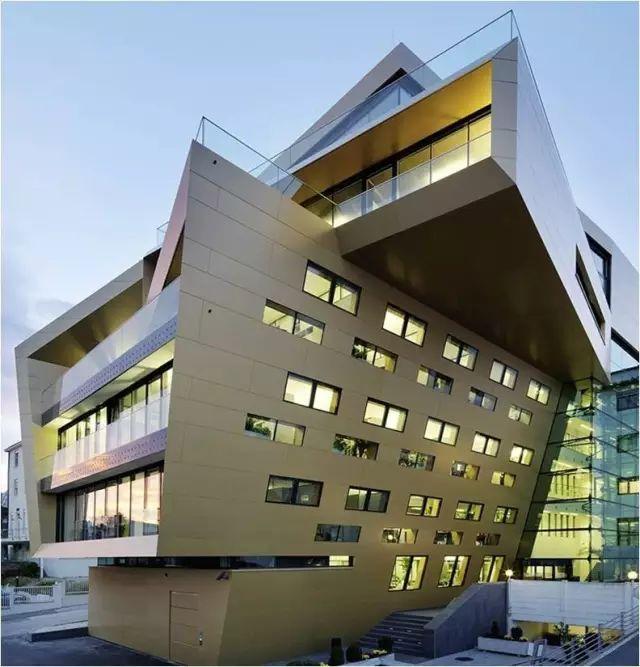

Aluminum plastic composite sheet application

The unique properties of aluminum plastic composite panels determine their wide range of uses: it can be used for building exterior walls, curtain wall panels, renovation of old buildings, indoor wall and ceiling decoration, advertising signs, display stands, purification and dust prevention project. It belongs to a new type of building decoration material.

Features of aluminum plastic composite sheet

Super peeling strength: The aluminum coated plastic sheet adopts a new process to improve the peeling strength, the most critical technical indicator of the aluminum-plastic composite panel, to an excellent state, so that the flatness and weather resistance of the aluminum plastic composite panel are correspondingly improved. .

The material is easy to process: The weight of aluminum coated plastic sheet per square meter is very light, so it can reduce the damage caused by earthquakes and is easy to transport. Its superior construction properties only require simple woodworking tools to complete cutting, trimming, edging, etc. It can be bent into various shapes such as arcs and right angles to make various changes. It is easy to install and reduces construction costs.

Excellent fire protection performance: The aluminum plastic panel has a flame-retardant PE plastic core material in the middle, and aluminum layers that are extremely difficult to burn on both sides. Therefore, it is a safe fire-resistant material that meets the fire-resistant requirements of building regulations.

Impact resistance: strong impact resistance, high toughness, bending without damaging the topcoat, strong impact resistance, and no damage caused by wind and sand in areas with heavy sandstorms.

Super weather resistance: Due to the use of PVDF fluorocarbon paint based on KYNAR-500, it has unique advantages in weather resistance. It will not damage the beautiful appearance no matter in the hot sunshine or cold wind and snow. Does not fade for 20 years.

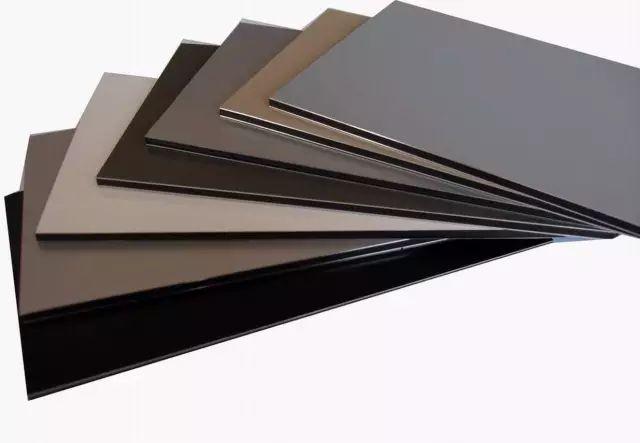

The coating is uniform and colorful: after chemical treatment and the application of Henkel film technology, the adhesion between the paint and the aluminum plastic panel is uniform and the colors are diverse, giving you more space to choose and showing your personalization.

Easy maintenance: Aluminum plastic panels have been significantly improved in resistance to pollution. The urban pollution in our country is relatively serious. Maintenance and cleaning are required after several years of use. Due to its good self-cleaning properties, only neutral detergent and clean water can be used. After cleaning, the board will always look like new.

Easy to process: Aluminum plastic panels are good materials that are easy to process and form. It is an excellent product for the pursuit of efficiency and time. It can shorten the construction period and reduce costs. Aluminum coated plastic sheets can be cut, trimmed, slotted, band sawed, drilled, and countersunk. They can also be cold-bent, cold-folded, cold-rolled, riveted, screwed, or glued.

Classification of aluminum coated plastic sheets by use

Aluminum plastic composite panels for building curtain walls - the minimum thickness of the upper and lower aluminum panels should not be less than 0.50mm, and the total thickness should not be less than 4mm. The coating should be fluorocarbon resin coating.

Classification of aluminum coated plastic sheets by function

Aluminum coated plastic sheet for exterior wall decoration and advertising - the upper and lower aluminum panels are made of rust-proof aluminum with a thickness of not less than 0.20mm, and the total thickness should not be less than 4mm. The coating generally uses fluorocarbon coating or polyester coating.

Aluminum coated plastic sheet for indoor use—the upper and lower aluminum panels generally use aluminum panels with a thickness of 0.20mm and a minimum thickness of not less than 0.10mm. The total thickness is generally 3mm. The coating is either polyester coating or acrylic coating.

Aluminum coated plastic sheet for building curtain walls - the minimum thickness of the upper and lower aluminum panels should not be less than 0.50mm, and the total thickness should not be less than 4mm. The coating should be fluorocarbon resin coating.

Aluminum coated plastic sheet for exterior wall decoration and advertising - the upper and lower aluminum panels are made of rust-proof aluminum with a thickness of not less than 0.20mm, and the total thickness should not be less than 4mm. The coating generally uses fluorocarbon coating or polyester coating.

Aluminum coated plastic sheet for indoor use—the upper and lower aluminum panels generally use aluminum panels with a thickness of 0.20mm and a minimum thickness of not less than 0.10mm. The total thickness is generally 3mm. The coating is either polyester coating or acrylic coating.

Classification of aluminum coated plastic sheet by decoration

Coated decorative aluminum plastic panels - various decorative coatings are applied to the surface of aluminum panels. Commonly used coatings include fluorocarbon, polyester, and acrylic coatings, which mainly include metallic colors, plain colors, pearlescent colors, fluorescent colors and other colors, which have a decorative effect.

Oxidation-colored aluminum plastic panels - Aluminum alloy panels are timely processed by anodizing and have unique colors such as rose red and bronze, which have a special decorative effect.

Film decorative composite board - that is, according to the set process conditions and relying on the action of the adhesive, the color pattern film adhesive is attached to the aluminum plate coated with primer or directly to the degreased aluminum plate. The main varieties include Gang pattern, wood grain boards, etc.

Color printed aluminum plastic panels - use advanced computer phototypesetting and printing technology to print different patterns with color ink on transfer paper to imitate natural patterns, and then indirectly copy various patterns on the aluminum-plastic panels through thermal transfer technology. An imitation of natural patterns.

Brushed Aluminum Composite Panel - An aluminum alloy panel with a brushed surface is used. Commonly used are gold brushed and silver brushed products, which bring different visual enjoyment to people.

Mirror aluminum plastic panel - The surface of the aluminum alloy panel is polished and looks like a mirror.