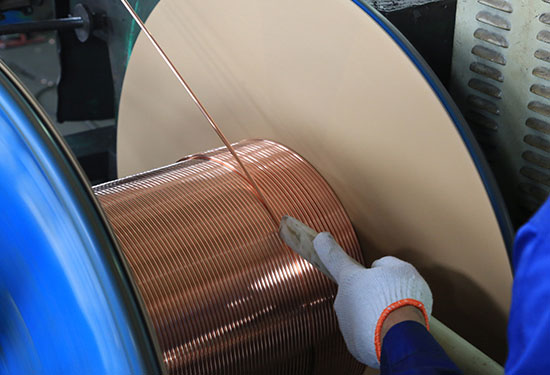

We have professional production experience in

copper clad aluminum cable. The annual output is 1500 tons. Our factory has four copper clad aluminum production lines. The products have strict quality inspection standards, the surface is smooth, no dents and bad defects, the wire diameter deviation reaches ± 0.0001 inches, and passed the ISO9001 quality system certification.

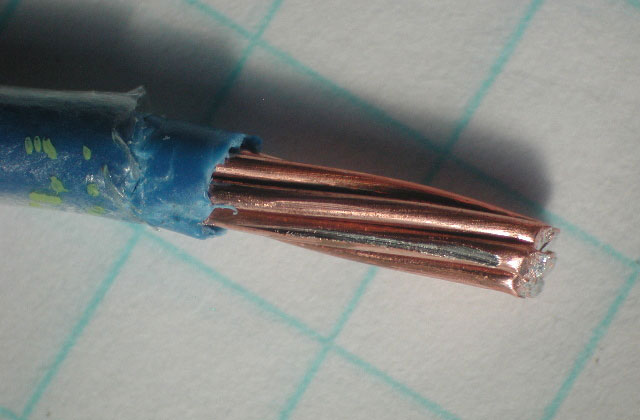

Copper clad aluminum cable refers to a wire and cable that uses an aluminum core wire instead of copper to become a main body of a cable and a certain proportion of copper layers.

Copper clad aluminum cables can be divided into two categories based on their use: one is

copper clad aluminum cable for signal or communication purposes, and the other is

copper clad aluminum cable for power supply.

Due to the high cost of pure copper materials, copper clad aluminum has been used in the field of coaxial cables and power cables in recent years. The

copper clad aluminum power cable adopts the cover welding manufacturing technology, which concentrically coats the high-quality copper tape on the outer surface of an aluminum rod or steel wire core wire and forms a strong metallurgical bond between the copper layer and the core wire. In this way, two different metal materials can be combined into an integral whole, which can be drawn and annealed like a single metal wire. During the drawing process, copper and aluminum are reduced in proportion to each other, and the volume ratio of the copper layer remains relatively constant.

Copper Clad Aluminum Cable Benefits:

1. DC resistivity: The resistivity of copper clad aluminum wire is larger than that of pure copper wire, which is about 1.5 times that of pure copper wire. When the same value of the cathode is reached, the weight of

copper clad aluminum power cable is about 1/2 of pure copper wire.

2. The use of copper-clad aluminum conductors can satisfy the habits of product selection, design, use, installation, etc. of wire and cable that are still to be continued for many years. It is also advantageous for tight pressing and soldering of the cable terminals.

3. reduce the AC resistance.

4. It has a good corrosion resistance: aluminum is more easily corrosion than copper, but because the copper clad aluminum material has been completely metallurgical, aluminum is completely covered by copper, will not be contact with water, air, fully achieve the same performance as copper.

5. Low cost and light weight:

copper clad aluminum power cable can save more than 40% of the cost compared with the copper cable with the same technical specifications. Copper-clad aluminum/copper composite conductor cable can save more than 20% of the cost. The proportion of

copper clad aluminum power cable is only 37%-40% of pure copper wire. With a wire diameter and weight equal to 2.5 times the length of the pure copper wire.

6. good welding:

Copper clad aluminum cable because of its surface concentric coated with a layer of pure copper, it has the same with pure copper wire solderability, convenient production.