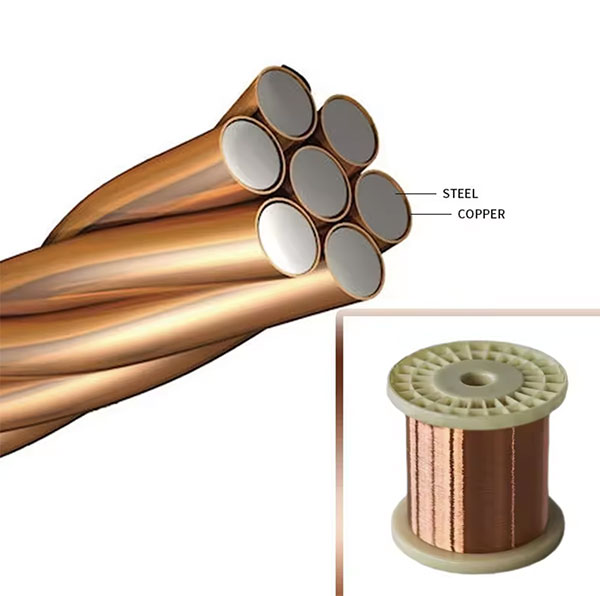

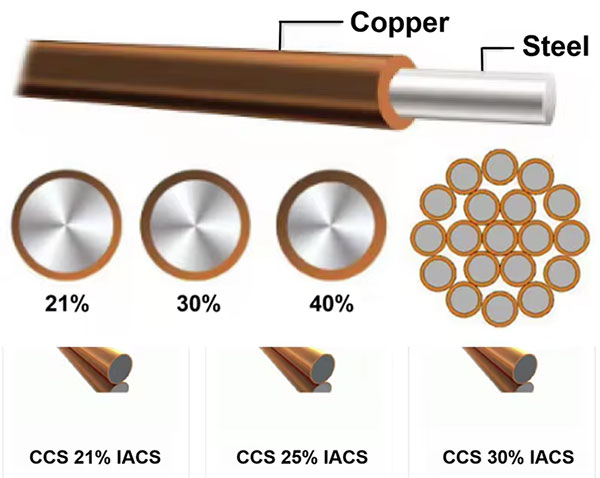

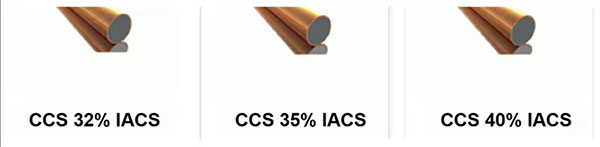

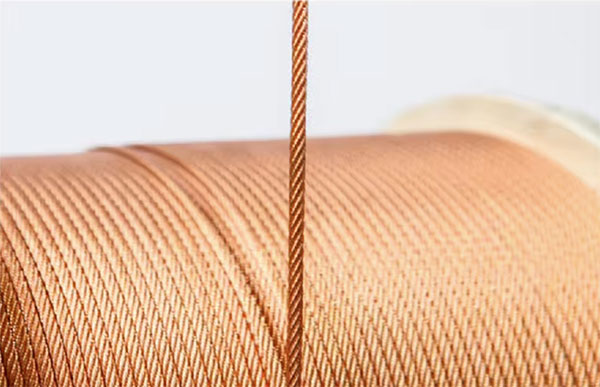

Copper clad steel wire (CCS Wire) is a composite conductor material typically used in telecommunications and electrical applications. It consists of a core made of steel and an outer layer of copper. The steel core provides strength and durability, while the copper coating facilitates excellent electrical conductivity. Our diameter range: 0.06mm - 0.9mm.

Advantages of copper clad steel wire

Cost-effectiveness: Copper is more expensive than steel. By using steel as the core material, the overall cost of the wire is reduced while still maintaining good electrical conductivity.

Strength: Steel provides mechanical strength to the wire, making it more resilient to stretching and breakage compared to pure copper wire.

Corrosion resistance: The copper coating protects the steel core from corrosion, extending the lifespan of the wire, particularly in outdoor or harsh environments.

Electrical conductivity: While not as conductive as pure copper, CCS still offers good electrical conductivity, suitable for many applications, including telecommunications and power transmission.

Weight reduction: Steel is denser than copper, so using a steel core reduces the weight of the wire while still providing the necessary strength.

|

Strand construction |

Elongation |

Tensile strength |

Diameter |

Lay direction |

Lay length |

DC-resistanceat 20℃ |

|

7x 0.16 CCSW |

Min.1% |

Min.750N/mm2 |

0.480+0.015mm |

S |

10-14mm |

≤317Ω/Km at 20℃ |

|

7x 0.18 CCSW |

Min.1% |

Min.750N/mm2 |

0.54+0.02mm |

S |

7-9mm |

≤250Ω/Km at 20℃ |

|

19x 0.12 CCSW |

Min.1% |

Min.750N/mm2 |

0.61±0.03mm |

S |

10-14mm |

≤203Ω/Km at 20℃ |

|

19x 0.18 CCSW |

Min.1% |

Min.750N/mm2 |

0.91±0.05mm |

S |

10-14mm |

≤87.8Ω/Km at 20℃ |

|

64x 0.10 CCSW |

Min.1% |

Min.750N/mm2 |

0.92±0.04mm |

S |

18-22mm |

≤94Ω/km at 20℃ |

|

5/0.13 CCAW |

Min.1% |

Min.750N/mm2 |

0.23-0.29mm |

S |

5-7mm |

640.7Ω/km at 20℃ |

Application of copper clad steel wire

We always seek to provide customers with the most innovative advanced technology, reliable high-end products and best services.copper clad steel wire have been widely used in automotive industry, industrial robot,medical equipment, railway, telecom industry, aerospace and other felds.

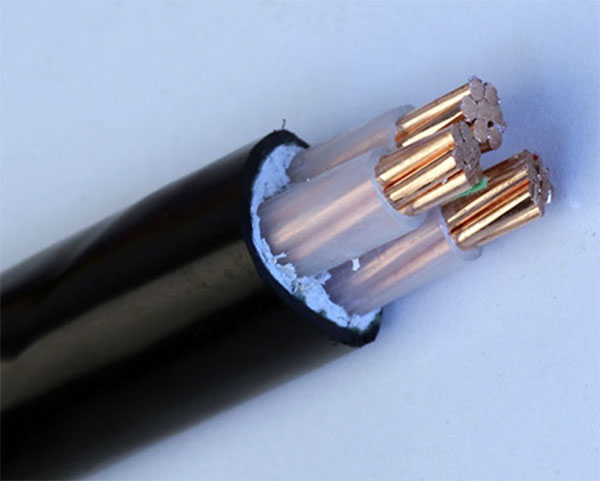

1. Limited TV subscriber line and nearhousehold wire coaxial conductor;

2. Computer LAN, access network cablefield conductor material;

3. Connectors for various electroniccomponents; power transmission andoverhead lines for telephone lines;

4. high temperature electronic wire conductor material;

5. core line of high temperature radio frequency cable;

6. electrified railway, rail line catenary, overhead line;

7. the braided shielding wire for power cables; grounding rods for electricpower industry; conductor materials for medical equipment and equipment.

Why choose us

Our CCS wire adopts advanced cladding welding and copper plating manufacturing technology.

The diameter precision of market product is ±5 %, our precision controlled to ±2 %. Whole inspection is adopted from raw materials to fnished products.

24-hour constant temperature and humidity workshop and warehouseWorkshop temperature is controlled at 5-35 °C,humidity<70%Warehouse temperature is controlledat 5-30 'C,humidity < 70%.

We are a leading supplier of highly advanced Cu wires and alloy wires based products and solutionsdeveloped in close cooperation with customers for electrical components applications and thecable industry.

Our businesscovers Asia, Europe, North America, Southeast Asia and other places of the world.