The

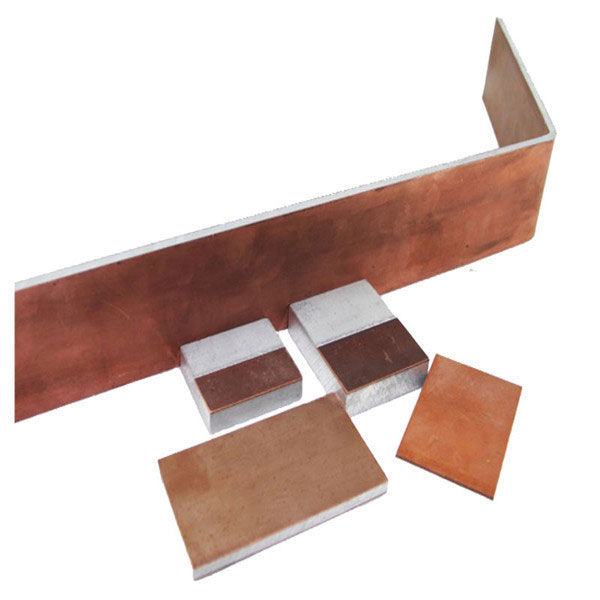

copper clad aluminum busbar developed and produced by our factory is widely used in transformers, reactors and other electrical industries, effectively replacing traditional flash welding and brazing processes. Our products have the following features:

1.We use advanced mechanical processing technology: solid-liquid processing technology, so that copper and aluminum are permanently and firmly bonded in an oxygen-free environment. Corrosion resistance and high temperature (no separation at 500 °C). We have applied for national patents and obtained ISO9000 certification.

2.Our

copper clad aluminum bus bars have high electrical conductivity, high mechanical strength, good reliability, low density, and cost savings.

3.Composite strength ≥ 12N/mm, composite rate: 100%; shear strength ≥ 35MPa; tensile strength: 90-130Mpa, elongation ≤ 35%;

4.Anti-corrosion, wear resistance, good electrical and thermal conductivity, and low cost.

5.Good mechanical properties: Excellent tensile strength, flexibility and ductility.

6.The

cca busbar has an aluminum to copper ratio of 8:2, and the ratio can be adjusted according to customer needs.

7.Both unilateral and bilateral copper edging can be provided.

8.With more than 98% conductivity, it can save 64% in the same volume and completely replace pure copper.

9.

We produce copper clad aluminum busbar width good stability, good deep drawing and tensile properties, even can withstand 90 ° without separation.

Specification:

|

Weight Display in Common Specification |

|

|

|

|

|

|

|

Specification a*b(mm) |

3*30 |

3*40 |

3*50 |

|

|

|

|

|

|

Weight/meter(kg) |

0.31 |

0.42 |

0.53 |

|

|

|

|

|

|

Specification a*b(mm) |

4*40 |

4*50 |

4*60 |

4*80 |

|

|

|

|

|

Weight/meter(kg) |

0.56 |

0.7 |

0.84 |

1.12 |

|

|

|

|

|

Specification a*b(mm) |

5*40 |

5*50 |

5*60 |

5*80 |

|

|

|

|

|

Weight/meter(kg) |

0.7 |

0.875 |

1.05 |

1.4 |

|

|

|

|

|

Specification a*b(mm) |

6.4 |

6*50 |

6*60 |

6*80 |

6*100 |

|

|

|

|

Weight/meter(kg) |

0.84 |

1.05 |

1.26 |

1.68 |

2.1 |

|

|

|

|

Specification a*b(mm) |

8*50 |

8*60 |

8*80 |

8*100 |

8*120 |

8*200 |

|

|

|

Weight/meter(kg) |

1.4 |

1.68 |

2.24 |

2.8 |

3.36 |

5.6 |

|

|

|

Specification a*b(mm) |

10*60 |

10*80 |

10*100 |

10*120 |

10*150 |

10*200 |

10*250 |

10*300 |

|

Weight/meter(kg) |

2.1 |

2.8 |

3.5 |

4.2 |

5.25 |

7 |

8.75 |

10.5 |