Copper is a good conductor. Titanium has good corrosion resistance in many chemicals. Composite materials composed of copper and titanium have good applications in the electrochemical industry. The production of

titanium clad copper material is most suitable for explosive welding.

Process parameters of explosive welding of titanium clad copper

|

Cover layer |

Grassroots |

h0

/mm |

Wg

/(g*cm-2) |

δt

/Mpa |

δf

/Mpa |

δb

/Mpa |

|

Metal |

Size/mm |

Metal |

Size/mm |

|

Copper |

2.5*710*710 |

titanium |

10*700*700 |

4 |

1.4 |

250 |

230 |

196 |

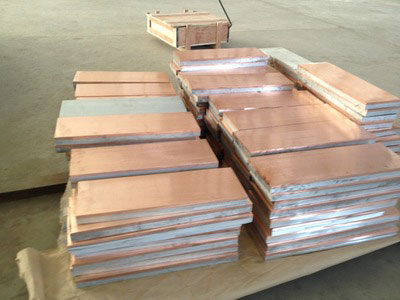

The types of products we produce include:

titanium clad copper plate, wires and rods.

Titanium clad copper will gain more and better applications in production and science and technology due to their superior physical and chemical properties. Here are some practical examples of some applications.

A composite plate type electrolytic cell in which a plant produces potassium chlorate by electrolysis has previously used a titanium plate as a corrosion-resistant structural material and as a conductive surface. The connection between the conductive copper plate and the titanium plate is pressed by bolts. In this case, if the current flows from the titanium to the copper, the surface of the titanium is rapidly passivated due to the high current density, resulting in an increase in resistance and severe heat generation, which causes the surface to be quickly passivated, resulting in an increase in resistance and severe heat generation, causing the electrolytic cell to be discontinued overhaul. The service period is only over 20 days. Later, a

titanium clad copper plate was used to bring the plate side into contact with the conductive copper plate. Since the interface resistance of the composite plate is only 13.5*10-7 Ω/cm2, the resistance of the entire cathode total plate is small and stable. Therefore, the problem of the point contact caused by the mechanical pressing and the sharp increase of the resistance is fundamentally solved. The conductive total surface of the cathode plate of this structure is expected to have an extremely long life.

titanium clad copper plate has achieved significant technical and economic benefits in this regard.

Titanium clad copper transition joints are used in the electrolytic nickel industry. This greatly reduces the electrical resistance of the same type of transition joint that was originally mechanically connected. Moreover, due to the high corrosion stability of the joint, its service life is increased by more than three times.

In addition,

titanium clad copper has found application in the alkali industry. Titanium clad copper pipe rods are also used in other electrochemical industries. Titanium clad copper plate has also been used together with

copper clad aluminum busbar as one of the new materials for the selection and testing of bimetallic liners.