Triplate aluminium/steel transition joint is a high-quality material that uses explosive welding technology to weld aluminum and steel, most commonly used in shipbuilding as a transition joint for hull structures.

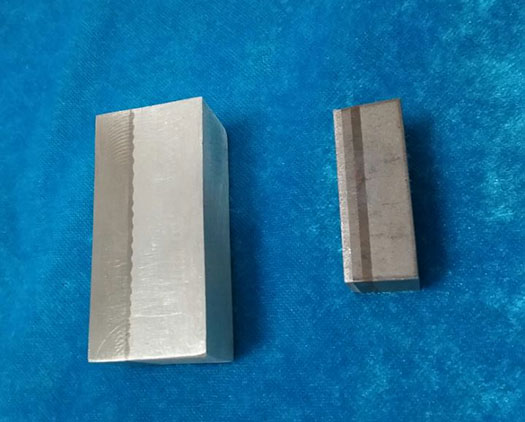

Triplate aluminium/steel transition joint is generally composed of a three-layer structure: steel, pure aluminum and seawater resistant aluminum alloy. The three layers are evenly bonded together using explosive welding technology. The specific parameters of each layer of material are:

Base: Steel (SS41)

Middle layer: pure aluminum (1050A)

Surface layer: 5083 aluminum alloy, etc.

|

Triplate |

Cutting interface |

Average value/Mpa |

Broken position |

|

A5083-A1050-SS41 |

A1050-SS41 |

87.2 |

Joint surface |

In the manufacture of marine vessels, the application of aluminum alloys is mainly to connect the aluminum structural members to the steel deck. In the past, such joints were riveted or screwed to ensure that the seal was not provided, thereby accelerating the corrosion of the seawater medium. Triplate is corrosion resistant and easy to process, which can be a good substitute for riveting. The Triplate also connects the aluminum superstructure, mast and antenna to the steel hull. This will reduce the ship's center of gravity and enhance the stability of the ship. Previously screwed, repairs were very difficult due to crevice corrosion, and the use of explosively welded joints reduced maintenance.

The mechanical properties of the

triplate aluminium/steel transition joint include the quality of the composite and the mechanical properties of the entire transition joint after welding. The former is completely dependent on the quality of the explosive composite, generally meets the requirements, and can also be tested by ultrasonic flaw detection, which is closely related to the design and construction process. When using Triplate, the interface temperature of the aluminum steel should be controlled to not exceed 300 °C. Because when the interface temperature exceeds 300 ° C, in addition to the mechanical properties will be reduced, it will also reduce the corrosion resistance of the composite zone.

Triplate aluminium/steel transition joint welding precautions:

(1) Welding is not allowed within 3mm of the aluminum steel interface.

(2) The steel-aluminum interface temperature is kept below 300 °C.

(3) The interlayer temperature shall not be higher than 200 °C.

(4) The transition joint cannot be preheated.

(5) Gas-cutting is not allowed for transition joints, only mechanical cutting.