al-cu bimetal materials is a new type of composite material. Its production methods mainly include rolling composite and explosive welding. Our company produces

al-cu bimetal materials mainly using explosive welding technology. We have rich experience in research, production, and sales of composite materials. The products have passed ISO9001 quality management system certification, the production capacity has reached 10,000 tons per year and sold at home and abroad.

al-cu bimetal materials are our main products. The specific product types include:

copper clad aluminum plate,

copper clad aluminum busbars, copper clad aluminum wire and so on.

With the development of science and technology, the requirements for materials in various fields have gradually increased. For example, in industrial production, not only cost savings, but also the consumption of precious metals as little as possible, but also the performance of the material is not affected.

al-cu bimetal material is produced under this condition. It has the advantages of good conductivity, high thermal conductivity, low contact resistance and beautiful appearance. It also has the advantages of light weight, wear resistance and low price of aluminum material. It can be said that it combines the chemical and physical properties of aluminum and copper to make up for the shortage of single materials, and has a very good application prospect. It is widely used in electronics, electrical appliances, electric power, machinery, automobiles and daily necessities.

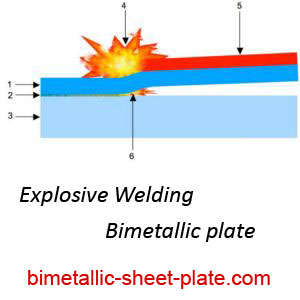

Explosive welding of

al-cu clad plate materials

The process installation and process parameters of

al-cu clad plate explosion welding are similar to those of other composite plates, but the thickness and area of the copper plate are not too large, and the strength of copper and aluminum is lower and the shape is higher, so the amount of explosive used is smaller. . Its explosive welding process is:

1. Prepare the metal material of the cladding and substrate to purify and handle the metal surface.

2. Prepare explosives, spacers and protective layers.

3. Install the material on the sand.

4. Explosive welding is carried out by detonating explosives.

5. Perform surface and appearance quality inspection of the fabricated

al-cu clad sheet.

6. Ultrasonic non-destructive testing of

al-cu clad sheet.

7. Perform cutting processing.

8. Grind and heat treatment as needed.

9. Packaging and shipping.

al-cu bimetal explosion welding parameters

1. Shear strength

|

Covering Plate |

Substrate |

h0

/mm |

Wg

/(g*cm-2) |

δT / Mpa |

|

Metal |

Thickness

(mm) |

Metal |

Thickness

(mm) |

1 |

2 |

3 |

4 |

5 |

Average |

|

Aluminum |

12 |

Copper |

10 |

8.5 |

1.7 |

66 |

78 |

76 |

75 |

71 |

73 |

2. Separation strength

|

Covering Plate |

Substrate |

h0

/mm |

Wg

/(g*cm-2) |

δT / Mpa |

|

Metal |

Thickness

(mm) |

Metal |

Thickness

(mm) |

1 |

2 |

3 |

4 |

5 |

Average |

|

Aluminum |

12 |

Copper |

10 |

8.5 |

1.7 |

87 |

73 |

73 |

106 |

87 |

85 |

3. Tensile properties

|

Thickness ratio |

1#(1:1) |

2#(1:1.5) |

3#(1:2) |

4#(1:3) |

5#(1:4) |

|

Tensile properties |

δb

/Mpa |

δ

/% |

δb

/Mpa |

δ

/% |

δb

/Mpa |

δ

/% |

δb

/Mpa |

δ

/% |

δb

/Mpa |

δ

/% |

|

1 |

300 |

10.8 |

281 |

7,9 |

284 |

7.3 |

278 |

6.9 |

254 |

6.6 |

|

2 |

305 |

10.1 |

290 |

12.0 |

284 |

7.0 |

279 |

6.6 |

271 |

6.5 |

|

3 |

|

|

283 |

7.7 |

|

|

|

|

|

|

|

Average |

303 |

10.5 |

285 |

9.2 |

284 |

7.2 |

279 |

6.8 |

263 |

6.6 |

Advantages of

al-cu bimetal explosive welding technology:

Our

al-cu bimetal products mainly use explosive welding technology. Metal explosion welding is a technology that combines metal physics, explosion physics, and welding technology. It has many features and advantages:

1. Explosive welding, as a new metal welding process and new technology, is unmatched by known welding processes. As long as the metal materials have a certain shape and impact toughness, they can be welded at any temperature and arbitrarily. Even materials with low shape and impact toughness can be welded by means of explosive welding. For the welding of metal materials, the utilization of various new energy sources will promote the development of welding technology. The use of this huge energy of explosives has made explosive welding a new welding technology in this field.

2. Explosive welding is a new process and new technology for bimetallic production, which is its greatest use. In particular, after the combination of explosive welding and various machining processes, the production methods and processes of other bimetallic materials will be eclipsed. Explosive welding has obvious advantages in terms of variety, specifications, products, quality, market, cost and efficiency. Practice has proved that the field of explosive welding materials is the enrichment and development of the material science system, and explosive welding materials are a new development direction.

3. At present, we have welded more than 300 pairs of metals with the same physical and chemical properties, similar or very different. The maximum area of the bimetallic plate reaches 300m2. Plates and plates, plates and tubes, and shaped parts can be explosively welded. In short, in the case of products which cannot be or are difficult to manufacture by conventional welding methods, explosive welding can be produced in principle.

4. Explosive welding joints microscopically combine the characteristics of pressure welding, fusion welding and diffusion welding, which provide more and better conditions for the bonding between different matrix metal atoms. Because of this, both the same and dissimilar metals can be explosively welded. Their bond strength withstands subsequent leveling, druming, cutting, welding, stamping, spinning, forging, drawing, rolling and heat treatment without delamination and cracking.

Therefore, explosive welding has such many characteristics and advantages, which is the reason for its independent existence, and it is the driving force for its wide application and rapid development. It is believed that with the continuous enrichment of time experience, the gradual deepening of theoretical research and the rapid expansion of application fields, the characteristics of explosive welding will become more and more fully manifested.