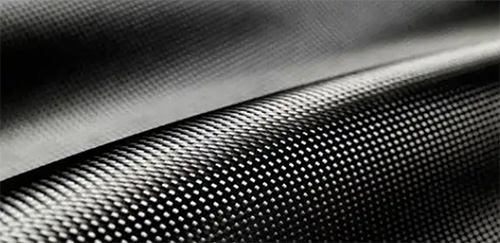

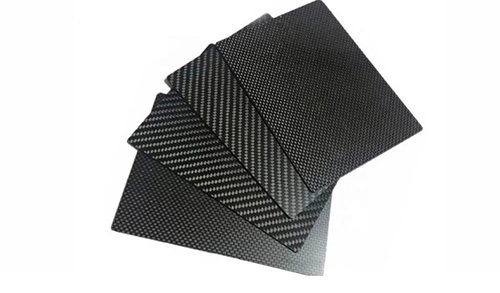

Carbon fiber composite material is a composite material with carbon fiber as reinforcement and polymer resin as matrix. Carbon fiber is a fiber material with a carbon content of up to 95%. It is ultra-light, high-strength, high-hardness, and has good wear resistance and corrosion resistance.

Features of carbon fiber material

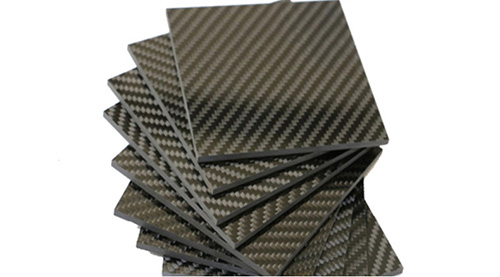

Mechanical properties

In various harsh temperature environments, it maintains good axial tensile strength and elastic modulus, and has good flexibility and fatigue resistance.

Small thermal expansion coefficient

The thermal expansion coefficient is small and anisotropic, with electrical and thermal conductivity, electromagnetic shielding performance, and strong X-ray transmittance.

Corrosion and fatigue resistant

Carbon fiber has high corrosion resistance and fatigue resistance and will not corrode for a hundred years.

High temperature resistance

Carbon fiber products are suitable for use in various harsh environments and can withstand temperatures ranging from -40°C to 100°C and above. (depending on the characteristics of the composite material.

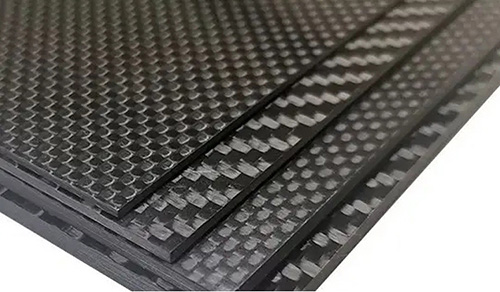

Advantages of carbon fiber composite materials

• High strength, 5 times that of steel; high stiffness, 2 times that of steel

• High strength-to-weight ratio, extremely light, easy material transportation

• High chemical resistance, therefore durable, low thermal expansion

• Short delivery chain, simple construction, less specialized labor required

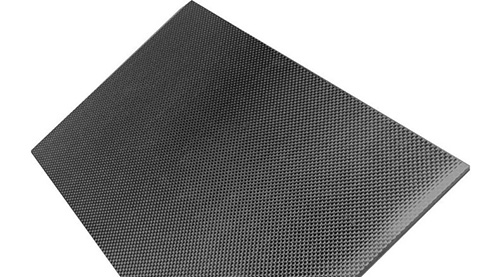

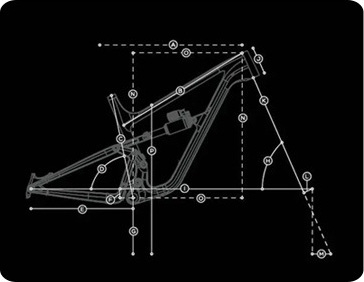

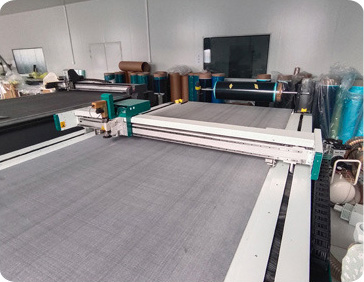

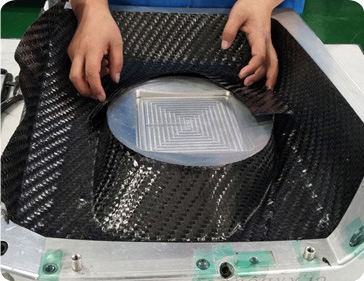

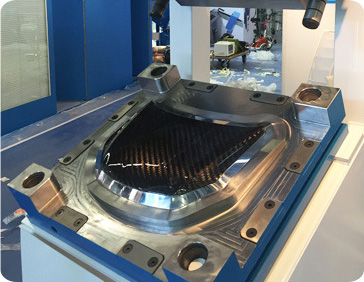

Carbon fiber composite materials process

• Design drawings

• Raw material production

• Raw material cutting

• Material film laying

• Hot pressing process

• Product demoulding

• Fine processing

• Quality inspection

Application of carbon fiber material

• Aerospace

• Military products

• Ship products

• New Energy Sources

• Rail

• Car

• Robot

• Medical instruments

• Sporting Goods