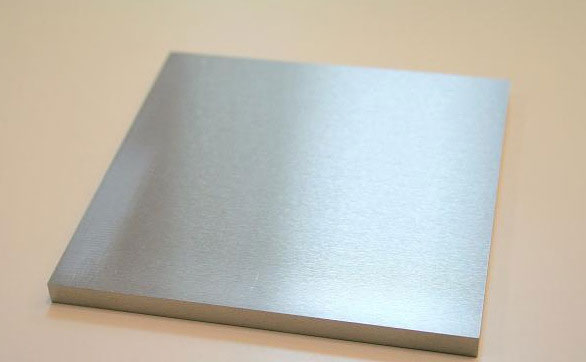

Titanium clad steel plate is a plate made of a common grade TA1 or TA2 (multilayer metal) and carbon steel or alloy steel by explosive welding, explosive welding + rolling or hot rolling. Titanium is a new type of metal with many properties such as low density, high strength, corrosion resistance and high and low temperature performance. It is an important structural material for aerospace, aviation, marine, chemical, power and metallurgical sectors.

Titanium clad steel plate can save titanium resources and reduce costs, and are widely used in industry.

The inner layer of the equipment made of

titanium clad steel plate is titanium, corrosion-resistant, the outer layer is steel, has high strength, the two layers are integrated into one body, has good thermal conductivity, and overcomes thermal stress, thermal fatigue resistance, pressure difference and The ability to withstand other loads can work under more demanding conditions. Therefore,

titanium clad steel plate has become an indispensable structural material for the modern chemical industry and the pressure vessel industry.

Titanium clad steel plate is increasingly used in petrochemicals and pressure vessels, and the use of such structural materials not only reduces the cost of the equipment, but also reduces the cost of the equipment. Moreover, it is possible to overcome many of the shortcomings of a single titanium device in this field.

Titanium clad steel plate production method:

The

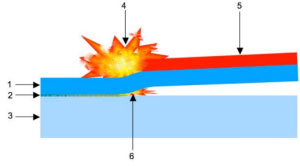

titanium clad steel plate produced by our company adopts the method of explosive welding. The explosive welding refers to the processing technology of using the energy of explosive explosion to weld different metal plates together. The installation process mostly uses the parallel method, and the detonation method mostly adopts the central detonation method. When exploding large-area composite plates, in order to ensure the support of the gap, a certain shape and number of metal spacers can be placed inside the two plates. In order to improve efficiency and better ensure the welding quality, symmetric collision can be adopted. Explosive welding processes are used to make such composite plates.

Product specifications:

Titanium alloy: TA1, TA2

Base carbon steel or alloy steel: Q235B, Q345B, Q245R, Q345R, etc.

Multilayer metal (titanium) thickness range: 0.5~12mm

Base metal (carbon steel or alloy steel): ≥ 3.5mm

Width ≤ 4500mm, length ≤ 15m