The

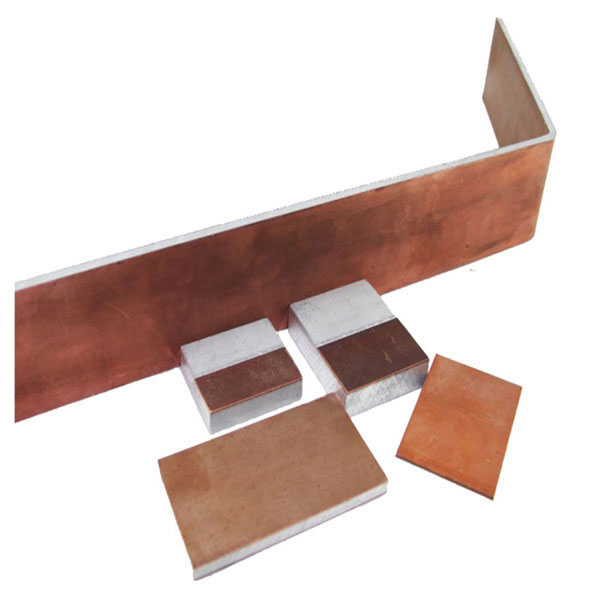

copper clad aluminum busbar is made of copper and aluminum. The bonding strength is very high. However, if the processing method is improper, it is easy to stratify. In the surface processing of

copper clad aluminum busbar, pay attention to the following items:

Fastening

When bolting the

copper clad aluminum busbar with bolts, an extra large washer is required. When there is a butterfly spring, a 2-3 mm thick steel plate is placed in the butterfly spring to disperse the pressure applied to the

copper clad aluminum busbar. Do not tighten the bolts too hard.

Surface passivation process

• The surface of the

copper clad aluminum bus bars is smooth and smooth.

• Drain the

copper clad aluminum bus bars into a passivation bath with a concentration of three thousandths of a passivation tank for 3-5 seconds.

• Remove the

copper clad aluminum bus bars for drying. The passivation solution is a CH-910 copper passivator with a chemical composition of benzotriazole, which does not cause chemical reaction to aluminum.

Copper clad aluminum bus bars current carrying reference table

|

Category |

Copper clad aluminum busbar specification(mm) |

The maximum length(mm) |

Weight per meter(kg) |

Ampacity(A) |

|

conventional |

3*25 |

6000 |

0.28 |

|

|

3*30 |

6000 |

0.32 |

|

|

3*40 |

6000 |

0.44 |

|

|

3*50 |

6000 |

0.54 |

|

|

4*30 |

6000 |

0.44 |

221 |

|

4*40 |

6000 |

0.575 |

272 |

|

4*50 |

6000 |

0.72 |

340 |

|

4*60 |

6000 |

0.86 |

408 |

|

4*80 |

6000 |

1.18 |

544 |

|

4*100 |

6000 |

1.52 |

|

|

4*120 |

6000 |

1.82 |

|

|

5*30 |

6000 |

0.54 |

255 |

|

5*40 |

6000 |

0.72 |

340 |

|

5*45 |

6000 |

0.81 |

381 |

|

5*50 |

6000 |

0.915 |

425 |

|

5*60 |

6000 |

1.09 |

510 |

|

5*80 |

6000 |

1.45 |

680 |

|

5.5*35 |

6000 |

0.69 |

|

|

5.5*45 |

6000 |

0.9 |

|

|

5.5*55 |

6000 |

1.1 |

|

|

5.5*70 |

6000 |

1.5 |

|

|

5.5*85 |

6000 |

1.8 |

|

|

5.5*110 |

6000 |

2.2 |

|

|

5.5*120 |

6000 |

2.5 |

|

|

6*30 |

6000 |

0.65 |

306 |

|

6*40 |

6000 |

0.86 |

408 |

|

6*50 |

6000 |

1.09 |

510 |

|

6*60 |

6000 |

1.31 |

780 |

|

6*70 |

6000 |

1.52 |

714 |

|

6*80 |

6000 |

1.74 |

816 |

|

6*85 |

6000 |

1.85 |

867 |

|

6*100 |

6000 |

2.18 |

1020 |

|

6*110 |

6000 |

2.4 |

|

|

6*120 |

6000 |

2.61 |

1224 |

|

6*140 |

6000 |

3.05 |

1428 |

|

6*150 |

6000 |

3.26 |

|

|

8*40 |

6000 |

1.16 |

544 |

|

8*50 |

6000 |

1.45 |

680 |

|

8*60 |

6000 |

1.74 |

816 |

|

8*70 |

6000 |

2.03 |

952 |

|

8*80 |

6000 |

2.35 |

1088 |

|

8*85 |

6000 |

2.52 |

|

|

8*100 |

6000 |

2.9 |

1360 |

|

10*40 |

6000 |

1.45 |

|

|

10*50 |

6000 |

1.81 |

850 |

|

10*60 |

6000 |

2.18 |

1020 |

|

10*70 |

6000 |

2.54 |

1190 |

|

10*80 |

6000 |

2.9 |

1360 |

|

10*100 |

6000 |

3.63 |

1700 |

|

10*120 |

6000 |

4.36 |

2040 |

|

10*125 |

6000 |

4.54 |

2125 |

|

10*140 |

6000 |

5.1 |

2380 |

|

12*120 |

6000 |

5.23 |

2448 |

|

10*150 |

6000 |

5.7 |

|

|

12*150 |

6000 |

6.8 |

|