Our company is a

bimetallic plate manufacturer integrating R&D, production and sales.

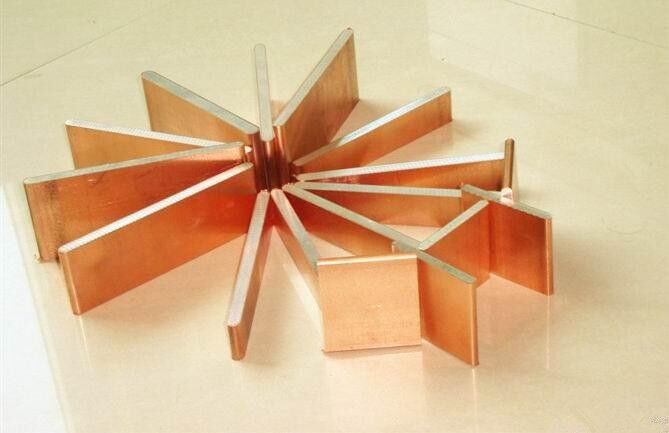

Copper clad aluminum busbar is our main product. We have done a series of performance tests in the laboratory.

The

copper clad aluminum busbar produced by the explosive welding method were tested for separation strength and bending under different test conditions. The test shows that both the inner and outer bends reach 180°, which meets the requirements of

copper clad aluminum busbar. The torsion test shows that it can generally reach 270°, 360° and multiple twists until the head is pinched off, and the separation of the coating from the substrate has not been found. The hardness test indicates that the hardness of the composite copper and aluminum sheets is increased, especially at the joint interface.

The electrical performance test results of the

copper clad aluminum busbar are as follows:

1. Aging test, aging test according to the predetermined method, the results show that the resistance value measured in the first 100 times does not change much, and the resistance value changes after aging test in 704 cycles does not exceed 10% (technical conditions stipulate not more than 20%) ), it can be seen that the

bimetallic busbar has good corrosion resistance, reliable and stable electrical properties.

2. High-current impact test. After 704 cycles of aging test, the

bimetallic plate board was subjected to 10 short-circuit current surges. The results show that the mechanical properties and resistance values remain good.

3. High-current continuous operation test, the

bimetallic sheet subjected to the above test is directly connected to the ground wire of the electric welding machine for high-current welding. The welding current is 320-420A, the time is 2h, and the load rate is 80%. The test results show that the temperature rise of the

bimetallic sheet portion does not exceed 80 °C.

4. If the fastening part of the

bimetallic plate is loosened, the temperature at the joint rises to 280 °C. In this case, the welding is performed. The results show that the temperature rise of the

bimetallic plate is close to 170 ° C, and the electrical conductivity is still good.

It can be seen from the above test results that the explosion-welded

copper clad aluminum busbar not only has good mechanical properties, but also has reliable and stable electrical properties, and is a rare structural material in the power, electronics and electrochemical industries.