We produce

bimetal aluminum steel plate using dynamic metal composite technology, also known as explosion method. Our core team has been engaged in dynamic composite technology research for more than 30 years, and has perfect technical standards and strict inspection system.

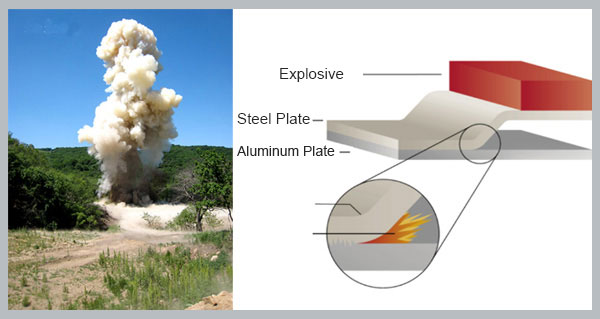

Our process for making

bimetal aluminum steel plate is probably like this. First, take an aluminum plate and a steel plate, stack them together, put explosives in the middle, and then explode. After the explosion, the aluminum plate and the steel plate are welded and the bonding surface is wavy.

After the explosion, the

bimetal aluminum steel plate will be bent and deformed, and it will be placed on a leveling machine to level the surface so that the

bimetal aluminum steel plate will be straightened and then cleaned.

Then, the

bimetal aluminum steel plate is cut in a cutting machine, the cutting size is according to customer requirements, and then the cut steel-aluminum composite board is subjected to edge treatment and rust treatment, and the production of the

bimetal aluminum steel plate is completed. Now.

The related

bimetal aluminum steel plate were tested and qualified for packaging. The

bimetal aluminum steel plate we produce are mainly used for shipbuilding. As a structural connection between hulls, the products are exported to more than 20 countries. The company has passed classification society certification and ISO9001 quality management system certification, and can purchase with confidence.