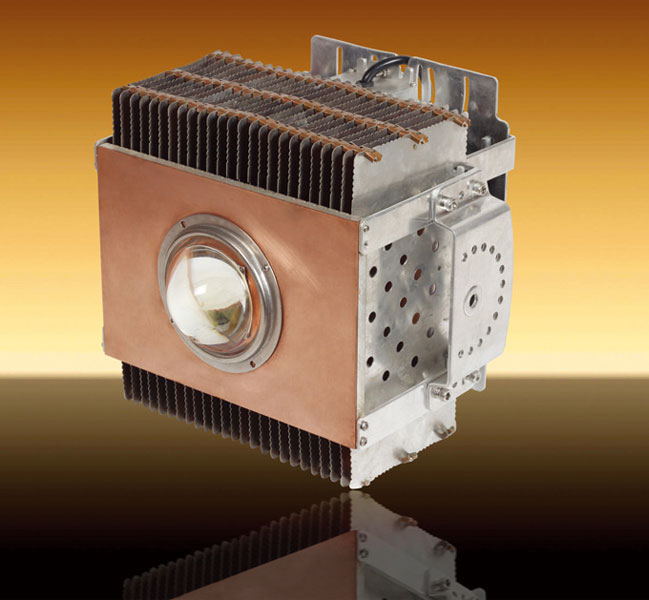

With the economic development, energy conservation and environmental protection have become the current trend. The LED industry is one of the most watched industries in recent years. Since its development, LED products have already had the advantages of energy saving, power saving, high efficiency, fast response time, long life cycle, no mercury, and environmental protection. However, usually, about 15% of input power of LED high-power products can be converted into light, and 85% of the remaining power is converted into heat energy. In general, if the heat energy generated when the LED emits light cannot be derived, the junction temperature of the LED will be too high, thereby affecting the product cycle, luminous efficiency, and stability. Copper has good thermal conductivity, aluminum has good heat dissipation,

copper aluminum clad sheet is an ideal new material that can not only improve the heat conduction and heat dissipation efficiency of LED chips, but also reduce the production cost. It is the LED packaging industry. development trend.

Our company has developed

copper aluminum bimetal sheet for LED package heat dissipation substrates through independent innovation, which fully utilized the thermal conductivity of copper materials and the heat dissipation performance of aluminum materials, enabling effective combination of the two metals. The miniaturization of high energy density is realized, and the heat dissipation system is also reduced in weight.

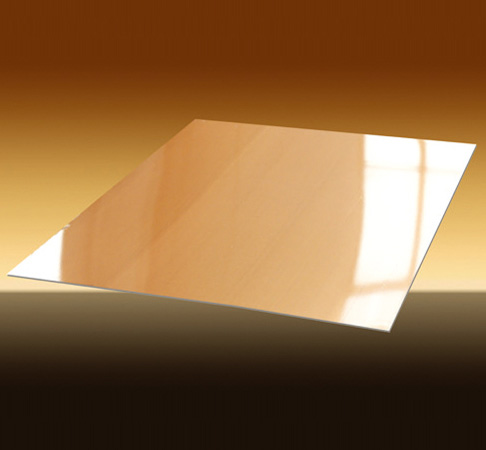

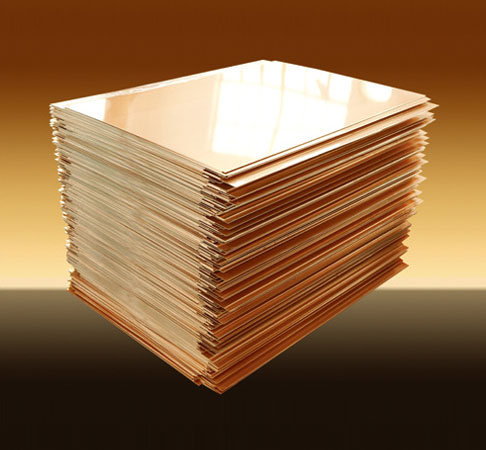

Copper aluminum bimetal sheet Size:

Thickness: 0.3-2.0mm, Width: 600-1000mm

Features:

Flatness, high mechanical strength, metallurgical bonding between copper and aluminum, extremely cold and hot, no delamination. The LED chip is directly encapsulated on the copper surface. The heat generated by the chip is transferred from the copper to the entire surface, and then is dispersed through the aluminum. This gives full play to the good thermal conductivity of copper and the good heat dissipation performance of aluminum.

Copper aluminum clad sheet is currently the most ideal COB package. Thermal substrate material.

Technical Parameters:

Composite rate: 100%

Tensile strength: 130-220Mpa

Elongation rate: 10-20%

Thickness ratio of copper layer: 10-20%