Our company independently researches and develops

Copper to aluminum transition plates materials, which are widely used in transformers, reactors and other electrical industries, effectively replacing the traditional flash welding and brazing processes. Mainly used in power plants, copper conductors and aluminum bus transition connection, can also be used for copper terminal and aluminum terminal clamp connection.

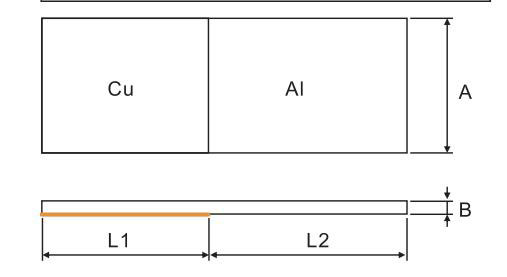

Copper to aluminum transition plates are mainly used to solve the problem of electro-chemical corrosion of the copper-aluminum joints of power equipment. According to the different connection methods, the design structure of

bimetallic transition plate is also not the same. As shown in the figure below, it can be roughly divided into two types:

1. left and right structure products, can produce a thickness of 0.2mm-20mm, copper and aluminum width requirements can be customized;

2. side composite structure, embedded structure, etc., can produce a thickness of 0.5-15mm;

3. composite strength: ≥ 12N / mm, composite rate: 100%; shear strength: ≥ 35MPa; tensile strength: 90 ~ 130MPa, elongation: ≤ 35%; DC resistivity: ≤ 0.0245Ω • mm2/m.

Details:

|

Place of Origin: |

Fujian, China (Mainland) |

Brand Name: |

China- grid |

Model Number: |

HJ |

|

Application: |

transition connector |

Material: |

Copper |

Dimensions: |

N |

|

Type: |

transition plate |

Material for body: |

Aluminum and copper |

Suitable conductors: |

aluminum bus bar |

|

Installation: |

Easy to operate |

Durability: |

Long |

Stability: |

High |

|

Mechanical Strength: |

High |

|

|

|

|

Packaging & Delivery:

|

Packaging Details: |

Wooden pallet |

|

Delivery Detail: |

7-21 days |

Product features: stable current transition, internal resistance less than 0.01 milliohms at the joint, close to the same kind of metal, long service life, strong transition bond, resistance to deformation of the tensile test test joint is greater than the deformation resistance of the aluminum substrate.

bimetallic transition plate have high conductivity, high mechanical strength, good reliability, low density, and cost savings.

Application:

Power transformers, reactors, bus ducts, welding machines, etc.

New energy automotive battery cover, PACK connection, etc.

Technical Parameters:

|

Type no |

Bus-bar

specification |

Dimension(mm) |

|

a |

b |

L1 |

L2 |

|

HJ-50*5 |

50*5 |

50 |

5.0 |

50 |

60 |

|

HJ-60*6 |

60*6 |

60 |

6.0 |

60 |

80 |

|

HJ-63*6.3 |

63*6.3 |

63 |

6.3 |

65 |

88 |

|

HJ-63*8 |

63*8 |

63 |

8.0 |

65 |

88 |

|

HJ-63*10 |

63*10 |

63 |

10.0 |

65 |

88 |

|

HJ-80*8 |

80*8 |

80 |

6.3 |

82 |

103 |

|

HJ-80*6.3 |

80*6.3 |

80 |

8.0 |

82 |

103 |

|

HJ-80*10 |

80*10 |

80 |

10.0 |

82 |

103 |

|

HJ-100*8 |

100*8 |

100 |

8.0 |

102 |

123 |

|

HJ-100*10 |

100*10 |

100 |

10.0 |

102 |

123 |

|

HJ-120*10 |

120*10 |

120 |

10.0 |

122 |

148 |

|

HJ-125*8 |

125*8 |

125 |

8.0 |

127 |

148 |

|

HJ-125*10 |

125*10 |

125 |

10.0 |

127 |

148 |

|

HJ-125*12.5 |

125*12.5 |

125 |

12.5 |

127 |

148 |