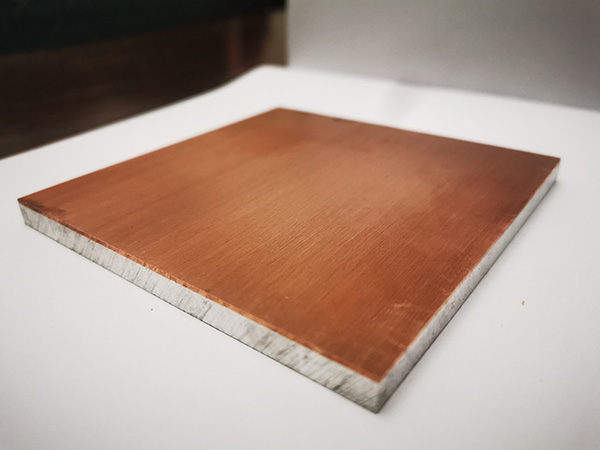

Copper clad aluminum is a bimetallic material composed of copper and aluminum. It is also our main product. What are the differences between it and copper?

1. Conductivity:

Copper: Copper is an excellent conductor of electricity, with high conductivity. It offers low resistance to the flow of electrical current.

CCA: While aluminum itself is a decent conductor, it's not as conductive as copper. The thin layer of copper in CCA helps improve its conductivity, but it still doesn't match the conductivity of pure copper. CCA typically has higher resistance compared to pure copper.

2. Cost:

Copper: Pure copper is more expensive compared to CCA due to its superior conductivity and other properties.

CCA: CCA is generally more affordable than pure copper, making it an attractive option for applications where cost is a significant factor.

3. Weight:

Copper: Copper is denser than aluminum, so copper wires are typically heavier than equivalent aluminum wires.

CCA: CCA wires are lighter compared to pure copper wires of the same gauge, which can be advantageous in some situations, especially for transportation and installation.

4. Corrosion Resistance:

Copper: Copper is highly resistant to corrosion, making it suitable for use in various environments, including outdoors and underground.

CCA: Aluminum is more susceptible to corrosion compared to copper. However, the copper layer in CCA provides some protection against corrosion. Nevertheless, CCA is still more prone to corrosion compared to pure copper.

5. Compatibility:

Copper: Pure copper wires are compatible with a wide range of connectors and equipment designed for copper wiring.

CCA: CCA wires may not be compatible with certain connectors and equipment designed specifically for copper wires. Special connectors may be required for CCA wires to ensure proper conductivity and reliability.

6. Strength and Durability:

Copper: Copper is a softer metal compared to aluminum, which can make it more prone to damage during handling and installation. However, it is highly durable over time.

CCA: Aluminum is a more rigid metal, providing better mechanical strength compared to copper. However, CCA may be more susceptible to damage from bending and flexing, leading to potential conductivity issues over time.

7. Heat Dissipation:

Copper: Copper has better heat dissipation properties compared to aluminum, making it more suitable for applications where heat buildup is a concern.

CCA: Aluminum has lower thermal conductivity compared to copper, which may result in slightly less effective heat dissipation in CCA conductors.

In summary, while copper offers superior conductivity, corrosion resistance, and compatibility, CCA provides cost savings and lighter weight. However, CCA may not be suitable for all applications due to its lower conductivity and potential compatibility issues. The choice between copper and CCA depends on the specific requirements of the application, including budget, performance needs, and environmental considerations.