Explosive welding is a new process for metal bonding. This new welding process requires cleaning of the metal joint before implementation. For example,

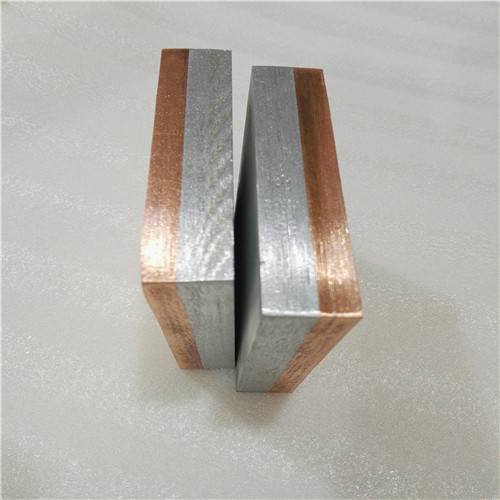

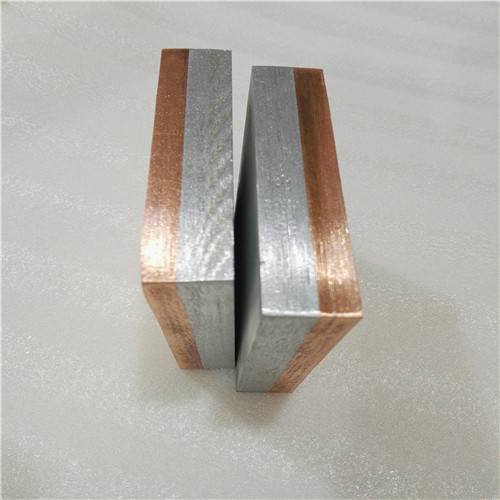

copper clad aluminum busbar,

aluminum steel transition joints, etc., must be cleaned and purified before the explosion welding.

It is well known that the welding of metallic materials is carried out under certain conditions, and the purification treatment of the parts to be welded is one of these conditions. Practice has shown that the more active the metal, the higher the cleanliness requirements, and some require vacuum. Even if the welding of ordinary steel requires cleaning of the oxide to be welded, the cleaning and purification is one of the basic requirements of the welding process for the metal material.

Why does the welding of metal materials require purification? The first condition for the welding of two metals is that the distance between the surfaces which must be separated from each other is the distance of the atomic distance by means of external energy under the action of external energy. At this distance, the gravitational and repulsive forces between the atoms tend to balance, and the metals are combined. Theory and practice have proved that due to the influence of the physical and chemical properties of metals on the welding process, it is easier to weld between the same metals, such as

copper clad aluminum. Welding between dissimilar metals is more difficult, and some are even impossible. If the welding between the same metal is mixed with other substances on the surface to be bonded, the welding process will be complicated. May bring difficulties to their combination, even if the welding strength is not high; It is also possible that the metal material that can be welded can not be welded.

The general cleaning process of the parts to be welded in the welding process is to remove and reduce the impurities in the welding position as much as possible, and to remove the influence of oxides, nitrides, oil and gas molecules on the welding process, in order to increase the weldability between the metals and Improve the bonding strength.